How Japanese woodcraft can inspire the Danish construction and help ease the climate crisis

How Japanese woodcraft can inspire the Danish construction and help ease the climate crisis

In August, Helena and Maki participated in the Building Green conference “Biobased Building Materials 2025.” Their presentation focused on Japanese reclaimed wood, a material rooted in tradition, combining circular design, a lower climate footprint, and healthier buildings.

They spoke about, among other things:

-

How the Japanese have built houses and temples from wood for more than 2,000 years, designed to be dismantled and reused.

-

The unique wooden joinery techniques, using no nails or screws, that make it possible to relocate and reassemble entire buildings.

-

Concrete experiences from the Kunitani House, a project where a traditional Kominka farmhouse was dismantled and rebuilt as a modern family home.

Helena and Maki at the conference ‘Biobased Building Materials 2025’

Why talk about Japanese reclaimed wood?

Japan is a country defined by its forests – around 65% of the land is covered in woodland. For more than 2,000 years, the Japanese have built homes and temples almost exclusively from wood, rooted in a deep respect for nature and a proud craft tradition passed down through generations.

From the first simple huts of the Yayoi period to the sophisticated temples of the Edo era, Japanese architecture has evolved with wood at its core. The arrival of Buddhism in the 6th century created the need for stronger joinery techniques, and during the Meiji period, Western influences blended with tradition. Yet, wood remains central to Japanese construction – even in the face of urbanization, an aging population, and a shortage of skilled craftsmen.

Japanese collab on circular construction

One of the most important principles in traditional Japanese timber architecture is Design for Disassembly (DfD) – the idea that buildings are constructed with the intention of being taken apart and reassembled. The structures are built using advanced wooden joinery without nails, screws, or steel. This makes them not only beautiful and durable but also highly reusable. Entire wooden structures can be dismantled and rebuilt elsewhere – preserving both the materials and the embedded craftsmanship.

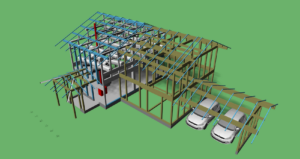

In collaboration with Sou Shin, a Japanese carpentry company, the large timber beams of the Kunitani House were carefully marked and transported 100 km to be reassembled as a modern single-family home, where traditional craftsmanship meets modern comfort, and with a significantly lower climate footprint.

The original Kominka farmhouse was built almost entirely from biobased materials (including timber felled in 1875) and showcased classical Japanese building techniques such as wattle-and-daub, where bamboo frames are filled with a breathable mixture of clay, soil, straw, and sand. The roof and walls were likewise constructed from natural materials such as bark, earthen plaster, and straw insulation.

- Kunitani House project, Japan

Even more advantages

There are more than 400 types of timber joints, often specific to Shinto shrines, Buddhist temples, or traditional houses.

These joints not only enable disassembly and reuse but also act as natural shock absorbers – ideal in a country plagued by earthquakes and typhoons. Design for Disassembly also has an economic benefit: if a building collapses during an earthquake, it can be quickly rebuilt, and only the damaged parts need to be replaced.

Natural indoor climate and lower CO₂

Biobased materials such as wood and clay act as natural regulators of humidity and temperature, creating a healthier and more comfortable indoor climate. Our life cycle assessment showed that by reusing wood instead of using new timber, the CO₂ footprint is reduced by 16% – and the savings increase to 33% if the old wood is not incinerated.

To put this into perspective: If the house had been built entirely with new timber, it would require more than 1,000 trees growing for 60 years to compensate for the emissions. By reusing the wood, this need is reduced to 690 trees.

What Denmark should learn from Japan

In Denmark, 90% of wood consumption is burned for energy production, while only 9% of construction uses wood – far behind Sweden and Norway. It is time to rethink wood in construction and apply the Japanese Design for Disassembly principles:

- Buildings can be designed to be dismantled and reused 1:1.

- Wood should be seen as a long-term resource, not fuel.

- Wood and other biobased materials can create healthier homes with a lower climate footprint.

Furthermore, we should extend the lifespan of wood, keep CO₂ locked inside buildings, reuse materials, and build with climate responsibility in mind – circular construction that will provide value for generations.

Are you interested in learning more? Contact Helena or Maki today.

- Post Categories

- Latest news